Binders Used for the Manufacturing of Composite Materials

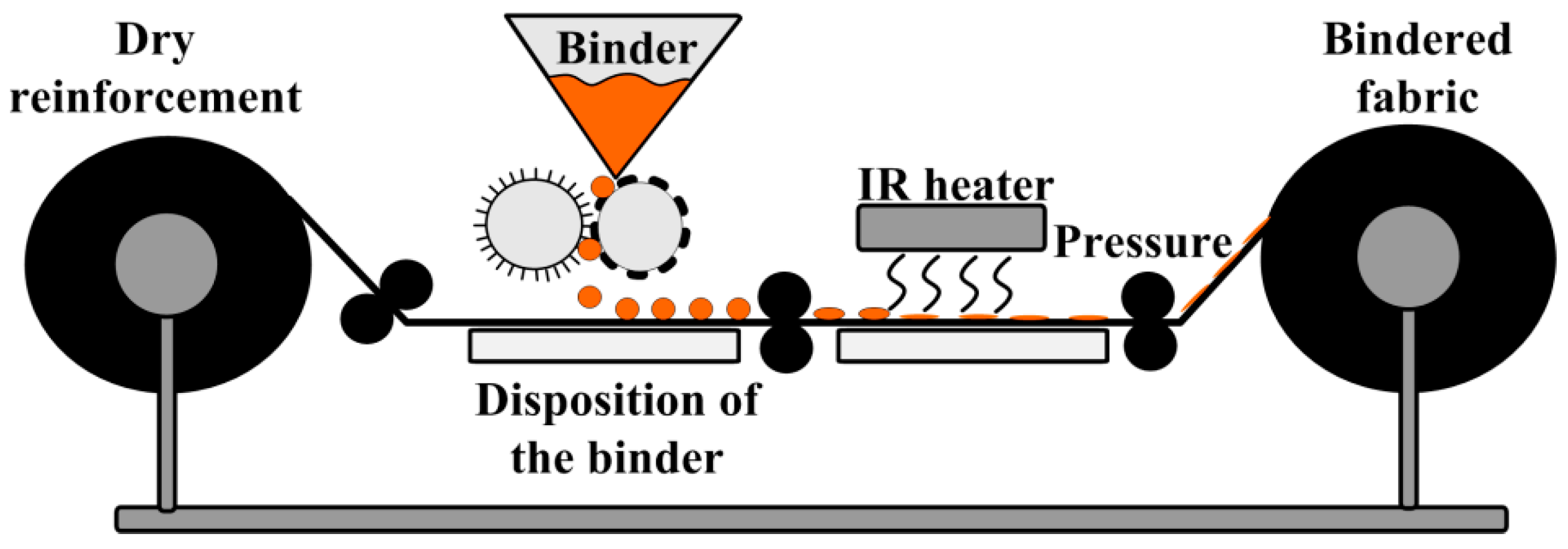

Binders, or tackifiers, have become widespread in the production of new composite materials by liquid composite molding (LCM) techniques due to their ability to stabilize preforms during laying-up and impregnation, as well as to improve fracture toughness of the obtained composites, which is very important in aviation, automotive, ship manufacturing, etc. Furthermore, they can be used in modern methods of automatic laying of dry fibers into preforms, which significantly reduces the labor cost of the manufacturing process.

Material extrusion for ceramic additive manufacturing with polymer

Manufacturing optimization zone diagram at different pressure boundary

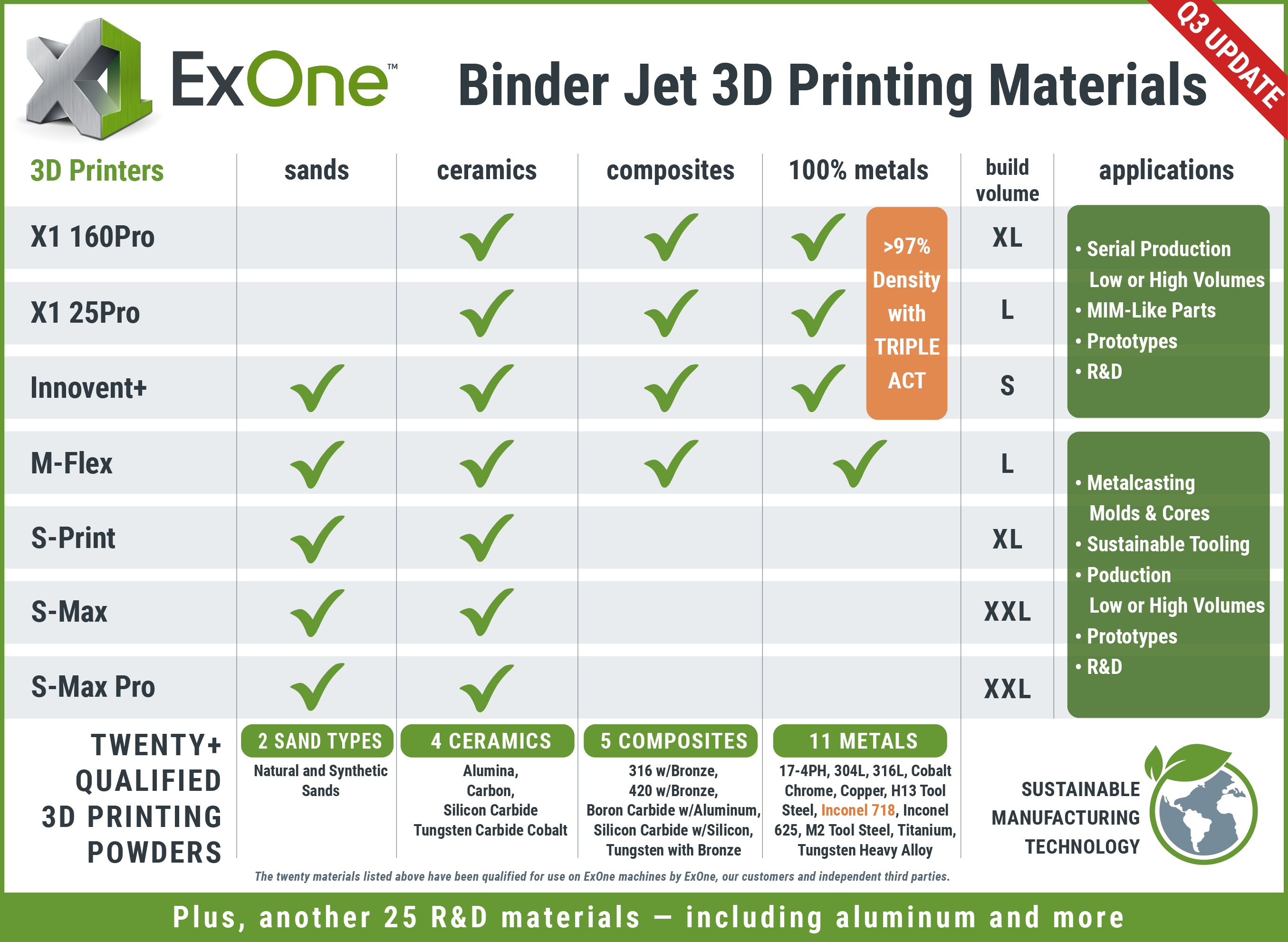

ExOne qualifies Inconel 718 for binder jet 3D printing - Make

Highly Branched Vinyl Ester-Based Binders for Elastomeric Roof

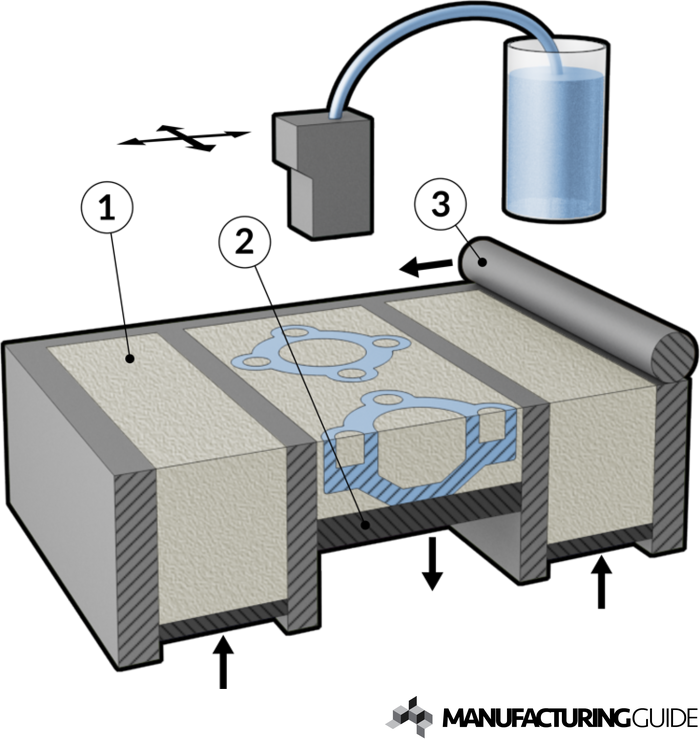

Lab based binding process Download Scientific Diagram

Polymers, Free Full-Text

All About Binder Jetting 3D Printing

Tufted specimen for permeability test (top left), surface microscopy of

Composite Binder - an overview

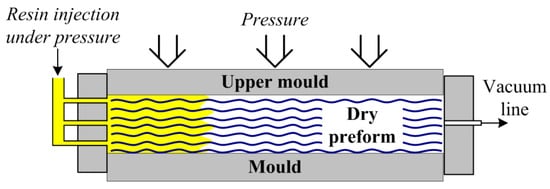

PDF] Optimizing Bladder Resin Transfer Molding Process to Manufacture Complex, Thin-Ply Thermoplastic Tubular Composite Structures: An Experimental Case Study

Binder Jetting 3D Printing – The Ultimate Guide

Green Building – Composite Lumber

Permeability of the fabric preform in the out-of-plane direction.

Microsections of the laminates after VARI process, spread SF rovings