Illustrative representation of a high velocity oxy-fuel (HVOF

Download scientific diagram | Illustrative representation of a high velocity oxy-fuel (HVOF) coating process; b powder particles coated on the substrate from publication: High velocity oxy-fuel (HVOF) sprayed coating nanoarchitectonics: influence of reduced graphene oxide (rGO) on tribological characteristics | In thermally sprayed tungsten carbide–cobalt (WC–Co) coatings, the hard WC particles perform as the wear-resistant part, while the cobalt act as binder and provides toughness. Due to their excellent properties, thermally sprayed WC–Co coatings have been widely used in many | Thermal Spray, Graphite and Graphene | ResearchGate, the professional network for scientists.

Materials, Free Full-Text

PDF) Numerical Modeling of In-Flight Characteristics of Inconel 625 Particles During High-Velocity Oxy-Fuel Thermal Spraying

Computerized detonation complex SSDS2000: (a) general view and (b

High Velocity Oxygen-Fuel

Illustrative representation of a high velocity oxy-fuel (HVOF) coating

What is HVOF?

Typical dependences of the friction force (F f ), friction

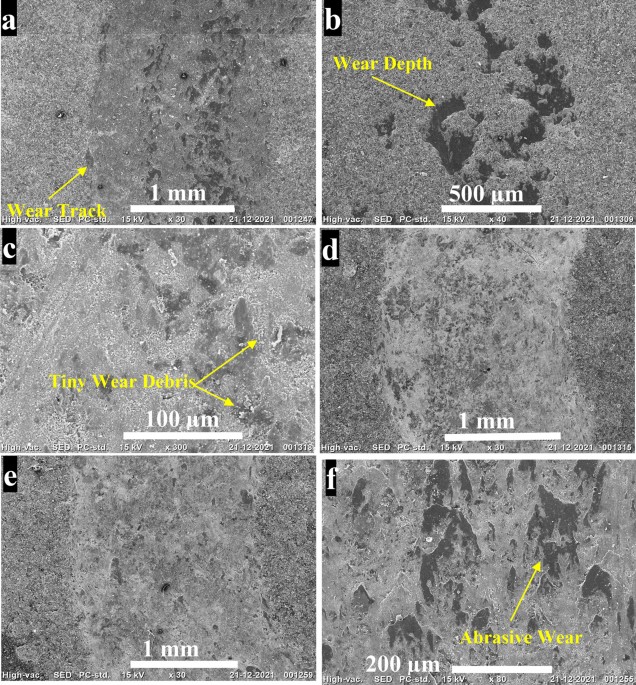

Laser and light microscopic images of the wear tracks after the

High-speed flame spraying (HVOF/HVAF) is used to produce hard

High velocity oxy-fuel (HVOF) sprayed coating nanoarchitectonics: influence of reduced graphene oxide (rGO) on tribological characteristics